Concrete & Deck Waterproofing

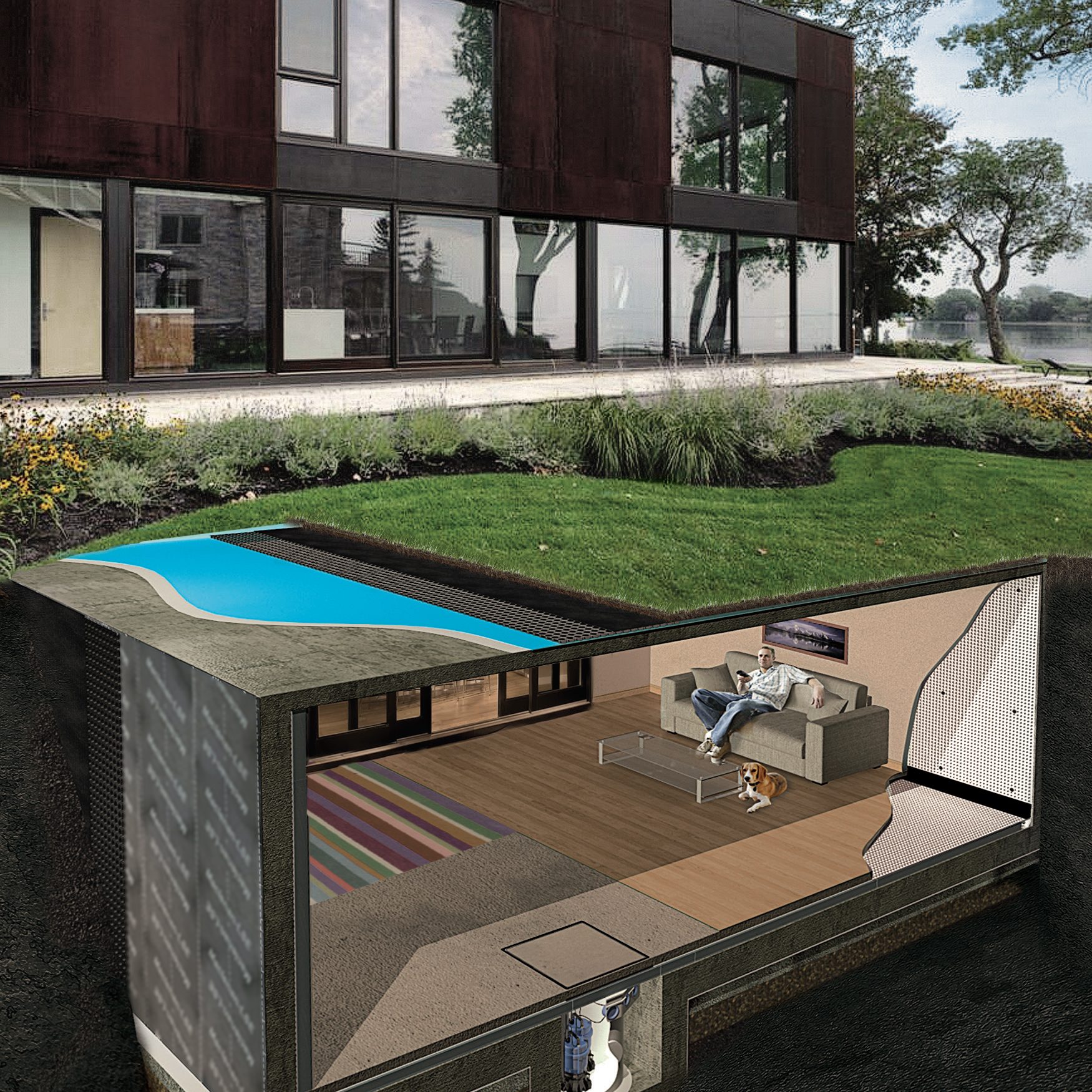

A concrete deck or buried roof is part of an under garden structure, and in most instances, tends to be part of a basement that extends beyond the line of the main elevations.

Our Specialities

- Podium decks

- Buried roofs

- External Type A waterproofing

- Water retaining pond linings and other uses

- Internal tank lining and protection

- Chemical resistant coatings for tank and bund linings

- Retention pond lining

- Encapsulation of hazardous materials such as asbestos

- Reservoir internal and external linings and coatings

Our Systems

Disclaimer

The following information is intended as advice only, to ensure that consideration is given to the detailing of concrete decks and buried roofs, which will allow waterproofing to be installed effectively.

Skip to sections

The Structure

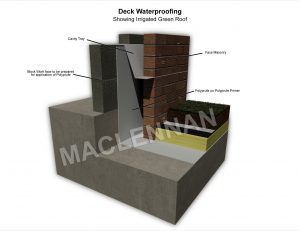

Many new buildings today are incorporating landscaped basements and roofs.

These basements can vary from habitable spaces to car parking.

Whatever the usage, the correct waterproofing system must be selected when waterproofing the deck area above the basement.

Concrete Deck or Buried Roof?

The concrete deck or roof is a structural element and should be designed by a structural engineer, to resist dead, live and wind loads. It must also resist weather events including storms, snow and localised flooding. Finally, it must also be suitable for the proposed waterproofing system, and subsequent use.

A waterproofing system for buried roofs needs to be particularly durable. Since the material will ultimately lie underneath landscaping or other finishes, it becomes very disruptive to have to make repairs if leaks occur.

You would have to remove the landscaping or other layer to identify where the leak is and then repair it. Because of this, waterproofing process’s and quality control need to be effective and third party testing should be carried out on completion to ensure the waterproofing will last for the life of the building itself.

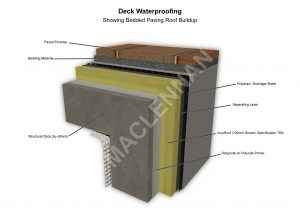

Inverted or Warm Roof?

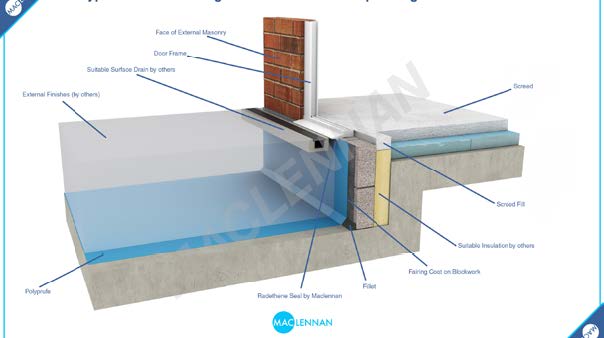

The waterproofing layer in a warm roof system is above the insulation installed above the roof deck. In an inverted roof, the waterproofing is above the roof deck, and beneath the insulation layer.

There is less risk of a leak if the waterproofing is directly on the structure as it is on an inverted roof. The consequence of a leak is less expensive and disruptive.

Joints, joins and detailing of insulation are more difficult for waterproofing. Water can track under insulation in the event of a leak, so locating a defect in the waterproofing can be difficult. For these reasons we always advise inverted over warm roof design.

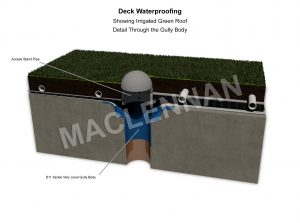

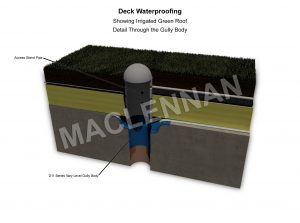

The drainage system must be designed by a drainage design engineer which provides efficient drainage of water from the roof or deck. Drainage has to be maintainable and maintained. Rainwater from other roofs should always drain directly to the drainage system at ground level and not onto or via balconies or decks.

Reinforced Concrete, the winner!

Podium Decks constructed from reinforced concrete and correctly designed by a competent engineer have proven to be the most reliable.

For Warranty purposes, Podium Decks constructed of block and beam floors or pre-cast concrete planks are not acceptable for any podium deck or buried roof applications.

Screeds can be used to achieve falls. The screed has to be of the highest quality and must be tested on completion to confirm strength and compaction before application of primers and coatings.

Drains and outlets must be designed and installed so water will run off uninhibited.

Block and Beam or Concrete plank

Block and beam and concrete plank are a quick and effective method of forming a deck, however they have to be finished with a concrete slab or a de bonded screed designed by a structural engineer so as it will not suffer from reflective or thermal cracking.

The screed has to be of the highest quality and must be tested on completion to confirm strength and compaction before application of primers and coatings.

What about metal decks?

It is not possible to achieve a defined datum level when constructing concrete slabs when installed on metal decking.

Deflection will occur which could lead to ponding. If there is a defect in waterproofing over a metal deck it will not be possible to establish the point of damage or defect by water testing.

Detailing

It is a requirement of third party warranty holders that waterproofing of buried roofs and decks is designed by a CSSW Qualified specialist (Certified Surveyor Structural Waterproofing).

This is critical to avoid split liability.

All posts and fittings should be detailed by the waterproofing specialist to ensure a complete and effective water proofing design and installation.

Rainwater pipes and service penetrations:

Must be at least 100mm clear of walls so effective waterproof detailing can be installed.

Where penetrations through a roof slab can be avoided they should be.

Drainage

The design of new Buried roofs and concrete decks should provide efficient removal of water to the designated drainage points. it must be maintainable and maintained.

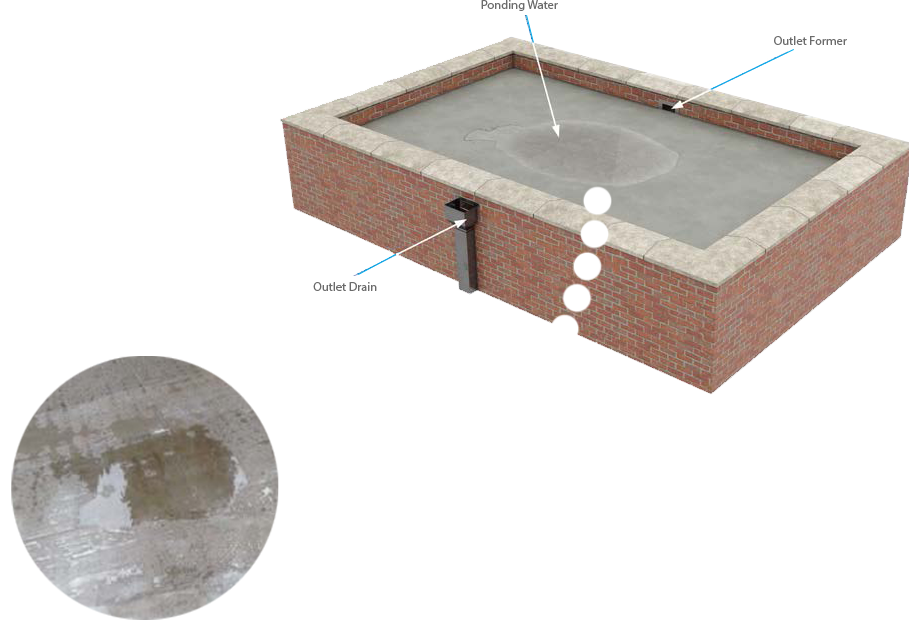

The drainage system must be designed by a drainage design engineer which provides efficient drainage of water from the roof or deck. There must be no back-falls or ponding on the roof. It is always better to design to falls to minimise risk.

Negative falls will result in ponding water which increases the localized load and the amount of water that could drain into the building through any defect or damage.

Finished concrete decks must be flood tested or analyzed by an engineer to confirm the deck is completely flat or to desired falls.

Ponding water will have a cooling effect on the roof deck below and so reduce the thermal performance

Surface Preparation

Grind it, vacuum it, check the temperature, check the moisture content, check the humidity. There is a lot more to waterproofing than just applying product.

Firstly, the area needs to be prepared by making sure it is clean and dry. To be assured of maximum adhesion of our system and to prevent outgassing, the correct surface preparation is essential. Substrates are mechanically prepared to remove all laitance, loose material, and contamination.

Concrete and Screed Surface Finishes

concrete/screed surfaces must be smooth and level, tamped concrete and ridges must be ground down. Ridges lead to shadowing in sprayed finishes which can cause defects and also more material is required for coatings.

Salt

Any project in close proximity to the sea risks contamination by air borne salt. Protection of concrete on completion of pouring is critical. Old concrete must be properly tested and prepared. Priming is critical and additional priming will be necessary to prevent the risk of osmosis as a result of salt contamination.

Laitance

New concrete will result in Laitance forming on the top surface of the concrete resulting in the lack of bond with any waterproofing. Laitance is water, cement and very fine aggregate on the surface of the sound concrete like a crust due to compacting of the concrete forcing the liquid content to the surface.

Laitance will be on the surface of old concrete unless it has been prepared previously.

This layer of laitance must be ground off back to the concrete and aggregate.

The surfaces must be clean and dry, dust, dirt, oil, grease, curing compounds or any foreign matter detrimental to the adhesion of the new waterproofing.

Voids, cracks, holes, honeycombs and other damaged horizontal or vertical surfaces must be repaired before application of the waterproofing.

Site Requirements

Safe access should be provided to the deck area.

An electrical supply must be available within 20m of work to the furthest area.

As with all coating systems there can be a strong odour for the duration of application. Site staff and neighbors should be warned of the odours and assured they are completely safe.

- Decks must be formed of concrete or structural screed to falls of 1:80 falling towards suitable drainage points

- Concrete and screed surfaces should have an engineers designed crack and movement control and be suitable cured prior to application of waterproofing system

- Decks should be protected from wet weather and tented in Winter or coatings cannot be applied

- Surfaces need to be visually dry, temperature has to be 5 degrees and rising. Relative Humidity has to be 3 degrees above dew point

- Concrete, screed or Asphalt has to be flat and smooth any indentations or depressions should be filled with an appropriate mortar

All concrete and screeds should have at least 28 days to cure and should have a moisture content of less than 5%

- Once cured all concrete and screeds should be covered to keep completely dry

- In Winter months this needs to tented to be effective

- Concrete / Screed surface should be sound clean and free of contaminates, loose particles or moisture

- All surface laitance need to be removed, this may be achieved using scarifying, grit blasting or water blasting although other methods are available

- Ensure that there are a suitable amount of drainage outlets for the surface area andthat they are maintainable

- All surfaces are to be dry, completely free of mud, debris, oil, tools, plant and material

- Provide any necessary de-watering

Get in touch with our technical team today!

Weather & Environmental Conditions

Site must be free from surface water, ice or snow prior to installation and with no forecast of rain for 48 hours after priming and 6 hours after work completion

Waterproof systems typically require an Ambient temperature of 5° and rising, 3 degrees above dew point and visually dry surfaces.*

*Some systems state 5% moisture or below 75% humidity.

De watering and drying is the responsibility of the site. The site are to provide a visually dry slab by either keeping it covered with tenting or drying with vacuums, squeegees and heaters prior to arrival of waterproofing Contractors so water will run off. uninhibited.

We advise all of our clients that deck waterproofing work must happen in the spring and summer. Winter work will be difficult, there could also be delays and additional costs.

In winter months or for time critical projects the deck must be fully covered with a temporary structure. All areas have to be visually dry.

Why should I work with MacLennan?

WE’RE INDEPENDENT

We Design, supply and install. There's no split responsibility with MacLennan.

WE’RE PASSIONATE

MacLennan live and breathe waterproofing, have a look at one of our free CPD seminars and find out!

WE’RE GUARANTEED

MacLennan has the most comprehensive guarantees and insurances in the industry.

Related Details

Related Projects

Grand & Luxury, New Build Home

Case Study / Waterproofing Grand & Luxury, New Build Home A specialist Waterproofing solution, for […]

Read MoreDeck Waterproofing Case Study / 19th century house, Wiltshire

Case Study / Deck Waterproofing 19th Century House, Wiltshire Waterproofing a deck above an indoor […]

Read MoreWaterproofing Case Study / Wembley Stadium, London

Case Study / Waterproofing Wembley Stadium, London Deck Waterproofing Wembley Stadium The stadium concourse was […]

Read MoreWhat else do you need to think about when waterproofing a basement?